TL-204C25

Excel

textlie\release agent \ink&varnish \metal coating\leather\

high melting point, wear resistance, scratch resistance, good smoothness, anti-adhesion 2, good transparency, suitable for high gloss system coating requirements.

LDPE

Keep it in a cool and closed place, and pay attention to anti-freezing

50KG/1MT CBM TANK

CHINA

| Availability: | |

|---|---|

| Quantity: | |

[Performance and Features]:

1. This cationic-nonionic system possesses strong formulation stability with cationic resins, and is suitable for application in acidic environment.

2. It has strong toughness, abrasion resistance, scratch resistance and block resistance.

3. It imparts good coating transparency, and is suitable for requirements for high gloss coating systems.

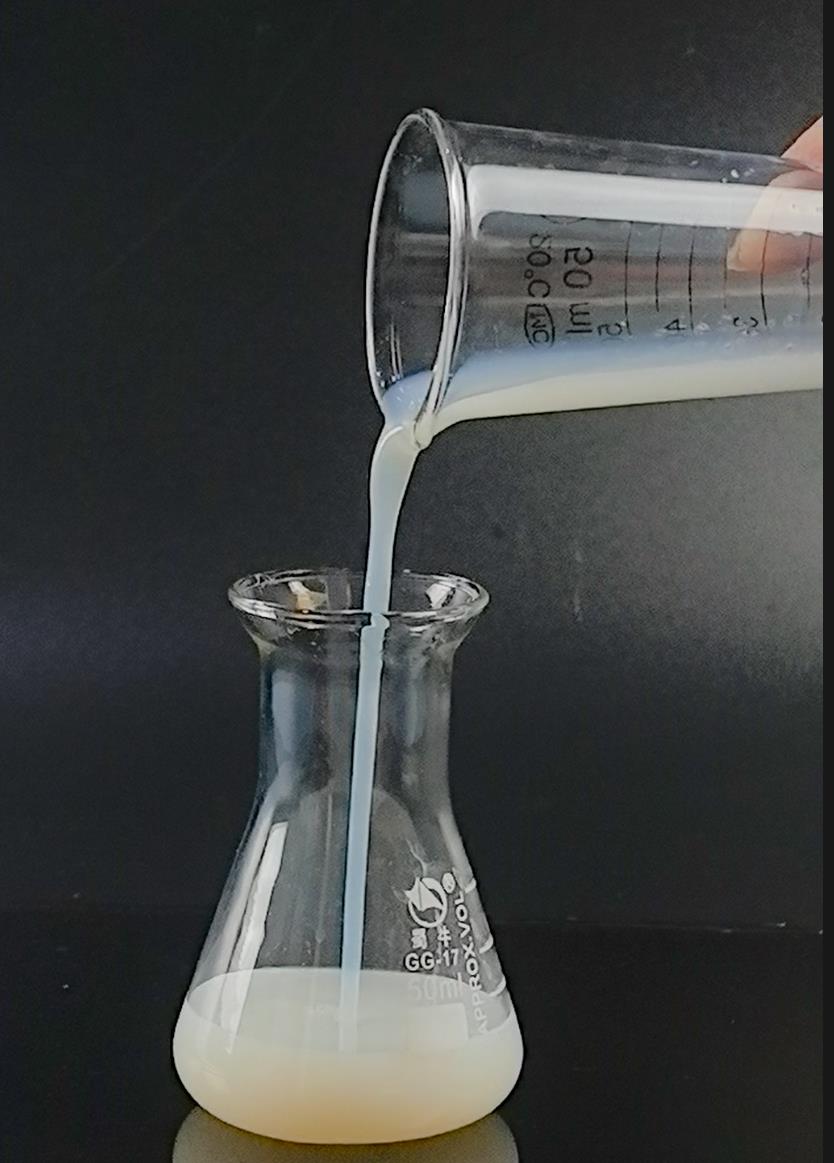

| Appearance | Light semi-opaque emulsion |

| Wax Type | LDPE |

| Emulsion System | Cationic-Nonionic |

| Melting Point(℃) | 95 |

| Solids (%) | 24.0-26.0 |

| Mean Particle Size (μm) | D50 ≤0.5 |

| PH | 3.5-5.5 |

| Application | Function |

★ Water-based ink, water based coating, water-based paint, and water-based varnish and water-based lacquer (metallic paint, wood paint, plastic paint, etc.), ★ Leather finishing agent, levelling agent, and anti-blocking agent ★ Textile smoothing agent, softening agent, and water resistant finishing ★ Polishing agent for flooring, leather, furniture, automotive, paper, etc. ★ Lubricant, release agent, adhesive, sizing agent for paper products ★ Organic surface modifying agent of the matting agent, agriculture, and other fields | 1.The ideal surface protective agent of water-based varnish abrasion resistance, scratch resistance, anti-blocking, and enhanced slip and gloss. 2. it enhances the fabric abrasion resistance, tear resistance, lubricity in the sewing, fabric softness of hand feeling, and it can also be applied in the printing paste. |

[Precautions]:

1. It shall be stored in closed packaging and in cool place. Prevent from freezing.

2. The shelf life of the product in the original packaging at room temperature is six months. Once the container is opened, it is recommended to use it completely in a short period of time.

3. To ensure the uniformity of the product, please shake up thoroughly before use.

4. Before mixed with resins, solvents, and other substances, please test the suitability in advance, especially take into account of pH. It is generally recommended that wax emulsion be added to the blending process at last.

5. This information is provided for reference only, and shall not be construed as guarantee.

| Image | Product Name | Brand | Product Code | Model | Appllication Area | Application Features | Specification | Store Temperature | Automatic Shutdown | Transport Package | Origin | User Manual Download |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V-2050 HDPE Micro-Disperson Wax Emulsion | Excel | V-2050 | Inks and Overprint Varnish | High solid content, the pursuit of abrasion-resistant and gloss balance, cost-effective, to achieve the performance level of the same type of foreign products, widely used in the field of water-based gloss oil and water-based plastic ink. | 50kg/drum、1CBM TANK(1MT) | 0-30℃ | 50kg/drum、1CBM TANK(1MT) | ||||

| TL-20140 HDPE Wax Emulsion | Excel | TL-20140 | Ink&Overprint Varnish | Wax emulsion is widely applied in textile coating to improve the block and thermal after-tack of coating and to achieve "Soft but not sticky". At the same time, it provides various kinds of feel (slipperiness, unsmooth, oil, etc.) for the coating, and can provide scratch resistance, adjust the luster, realize the "Lotus leaf hydrophobic" effect and other functions. It can be used as a yarn lubricant to improve yarn lubricity and reduce friction. After special pressing process, it can achieve brightening effect and easy to wash. It can be used as a soft finishing agent for fabrics to obtain a soft and fluffy feel, while mechanical properties, drape and lubricity are improved. It can effectively improve abrasion resistance, tear resistance, wrinkle recovery performance, reduce stitch cutting, reduce needle temperature and reduce needle wear in resin finishing. | solid content 40% | 5-35℃ | 50KG DRUM AND 1MT CBM TANK | CHINA | TL-20140 HDPE D50 0.2-0.4 修改.pdf | ||

| TL-2011C25 HDPE Wax Emulsion | Excel | TL-2011C25 | WAX Emulsion TL-2011C25 EN HDPE 阳离子及非离子 D50 ≤0.1 修改.pdf | ||||||||

| V-815A Wax Dispersion | Excel | V-815A | It is recommended to place it in a closed and cool place and pay attention to anti-freezing. | 500G/BOTTLE,25KG/DRUM/,200KG/DRUM,1MT/DRUM | 5℃-35℃ | V-815A 英文版TDS .pdf |